ARPX Series

AR FILTRAZIONI | ARPX Series

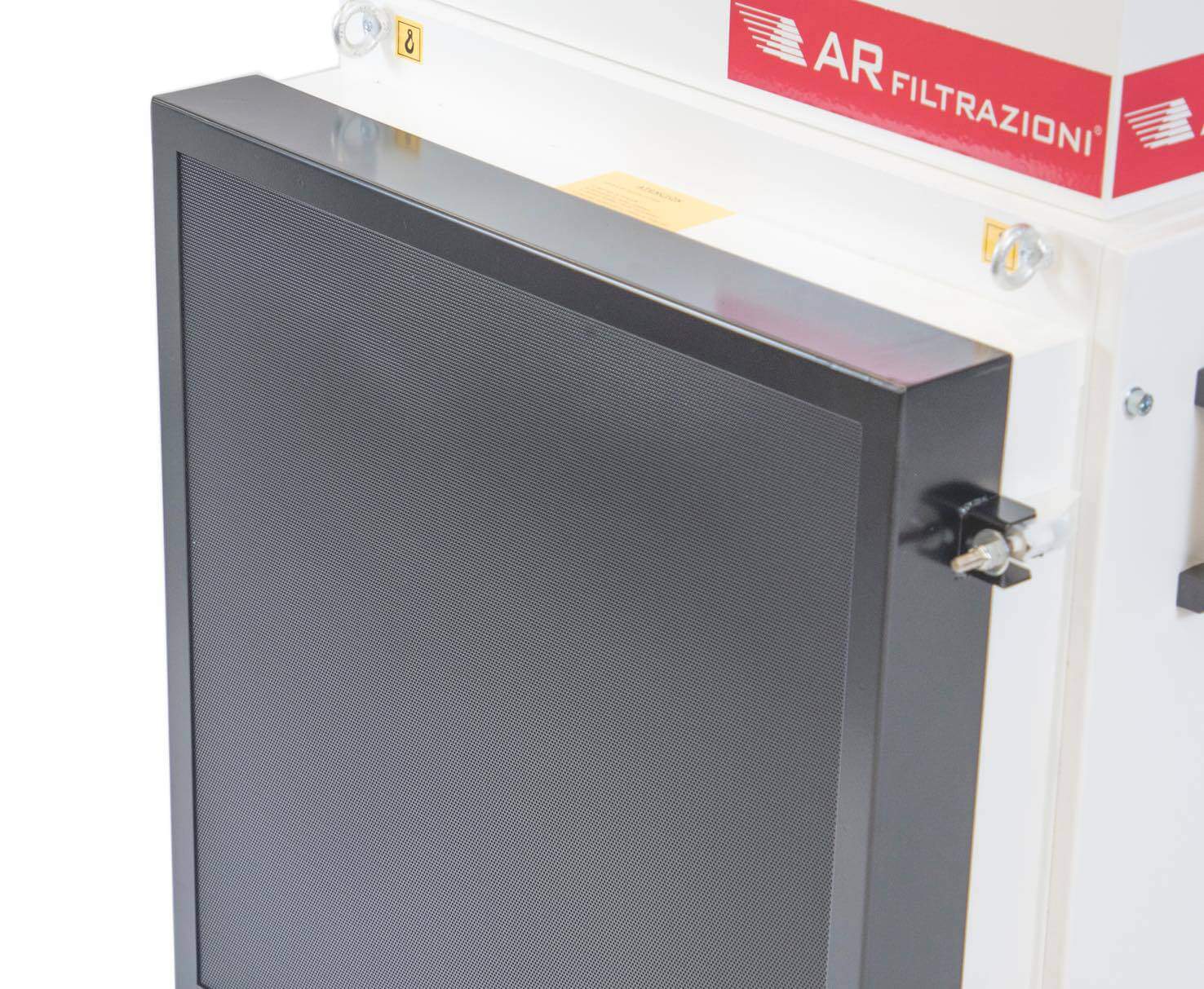

The ARPX Series is suitable for its versatility in mixed and periodic processes, it is modular and agile in moving.

The ARPX Series is suitable for the extraction and purification of fumes, odors and dust generated in dry and wet processing. of constructive strength and maintenance management. The technical construction features give the purifier a versatility and robustness over time.

With a new layout of its componentry (motor, pocket filters and 2 high efficiency filters), the ARPX series represented a complete break from the centrifugal purification technology in vogue at the time.

The principle of operation for

ARPX Series

Indicated for the extraction, re-condensation and purification of the fumes, exhalations, odours and dusts generated during dry and wet machining, the series is ideal for purifying particles of variable sizes by simply using interchangeable filters of different filtration efficiencies. The first purifier designed and manufactured by AR FILTRAZIONI, aimed at satisfying the requirements of the market in terms of robust construction and ease of maintenance, to stand out from the competition it had to be MULTIFUNCTONAL AND ROBUST to satisfy the varying needs of a mechanical engineering workshop.

With a new layout of its componentry (motor, pocket filters and 2 high efficiency filters), the ARPX series represented a complete break from the centrifugal purification technology in vogue at the time. The young founders of AR FILTRAZIONI had understood that centrifuges (which still account for the majority of commercial oily mist purifiers) had too many problems: malfunction due to wear of the centrifuge motor bearings, vibration under heavy load. Quite apart from maintenance, which was then and still is very complex, since the purifier must be uninstalled for routine maintenance, which means long downtimes (just try opening a barrel of special fluid waste, positioned horizontally or, even worse, vertically with its opening at the bottom!).

In contrast, with the ARPX series you need only open a hatch to remove and replace the pocket filters. Two high efficiency filters are located at the sides and fit under pressure. The series is composed of 2 sub-series, with flow rates from 2000 to 3200 m³/h. The ARPX series, which has been on the market for 15 years, and is completely compliant with current legislation, fully satisfies the requirements of intense production: it is compact, robust, efficient, needing little maintenance which is quick and easy when necessary, and is regulated by a visual filter clogging indicator. Equipped with a dual high and very high efficiency filtration stage, EN 1822 compliant, it ensures filtration of up to 99.995% of particles > 0.15 µ (note that the mean diameter of fumes particles is always < 1 µ).

SUITABILITY

Indicated for the extraction, re-condensation and purification of the fumes, exhalations, odours and dusts generated during dry and wet machining, the series is ideal for purifying particles of variable sizes by simply using interchangeable filters of different filtration efficiencies. Thanks to its modular design, each purifier is equipped with a high (EPA) and very high (HEPA) efficiency filter stage, compliant with EN 1822, and suited for reducing micro-dust, micro-mist and fumes. The purifier can be equipped with a further dual stage composed of two active charcoal cells for eliminating noxious exhalations and odours. The series is equipped with low energy consumption motor rated class IE3, with a motor thermal cutout and visual filter clogging indicator. It is fitted with a drain system for recovering the condensed fluid.

OPTIONAL ACCESSORIES

- – SELF-SUPPORTING ARTICULATED BOOM

- – ACTIVE CHARCOAL CELL FOR REDUCING ANY EXHALATIONS AND ODOURS

- – NOISE ATTENUATOR

- – DEVICE TO MONITOR FILTER CONDITION

Working principles ARPX Series

1st STAGE

PREFILTRATION European standards EN779 Filtration efficiency> 95% - Particles with volume 3 μ2nd STAGE

FILTRATION WITH COALESCENCE EFFECT European standards EN779 Filtration efficiency up to 95% - Particles with volume 0.4 μ3rd DOUBLE STAGE

DIFFUSER / NOISE REDUCER4th DOUBLE STAGE

FINAL PANEL FILTERS IN POLYURETHANEErba Spa has chosen

AR Filtrazioni for its machinery fleet.

Technical features "ARPX Series"

Technical Features

| Models | Suction inlet Ømm | Max airflow m3/h | Power kW | Voltage - Frequency V - Hz | Noise level dBa | Overall dimensions mm | Weight Kg |

|---|---|---|---|---|---|---|---|

| AR2PX – AR2PX AE | 150 | 2400 | 1,5 | 230/400 – 50 | 72 |

A:700 B:950 H:1200 | 110 - 120 |

| AR2PX AE M | 150 | 2400 | 1,5 | 230/400 – 50 | 72 |

A:700 B:1400 H:1200 | 130 |

| AR2PX CA | 150 | 200 | 1,5 | 230/400 – 50 | 72 |

A:700 B:950 H:1200 | 160 |

| AR3PX – AR3PX AE | 200 | 3200 | 2,2 | 230/400 – 50 | 76 |

A:700 B:950 H:1300 | 120 - 130 |

| AR3PX AE M | 200 | 3200 | 2,2 | 230/400 – 50 | 76 |

A:700 B:1400 H:1300 | 140 |

| AR3PX CA | 200 | 300 | 2,2 | 230/400 – 50 | 76 |

A:700 B:950 H:1300 | 170 |

AR FILTRAZIONI SERVICE AND MAINTENANCE

SERVICE for AR Filtrazioni means:

TOP REFERENCES AR FILTRAZIONI

AR Filtrazioni units at work

Here are some of the AR Filtrazioni top references that have chosen AR Filtrazioni for their machine tools.

Learn how to reduce oil consumption, save on conditioning and reduce CO2 emissions.

Fill out the form and our calculation system will immediately quantify the savings you can get and send you the results by email.