CNC machining centers

AR FILTRAZIONI | CNC machining centers

The filtering solution to all type of pollutants for CNC machining centers

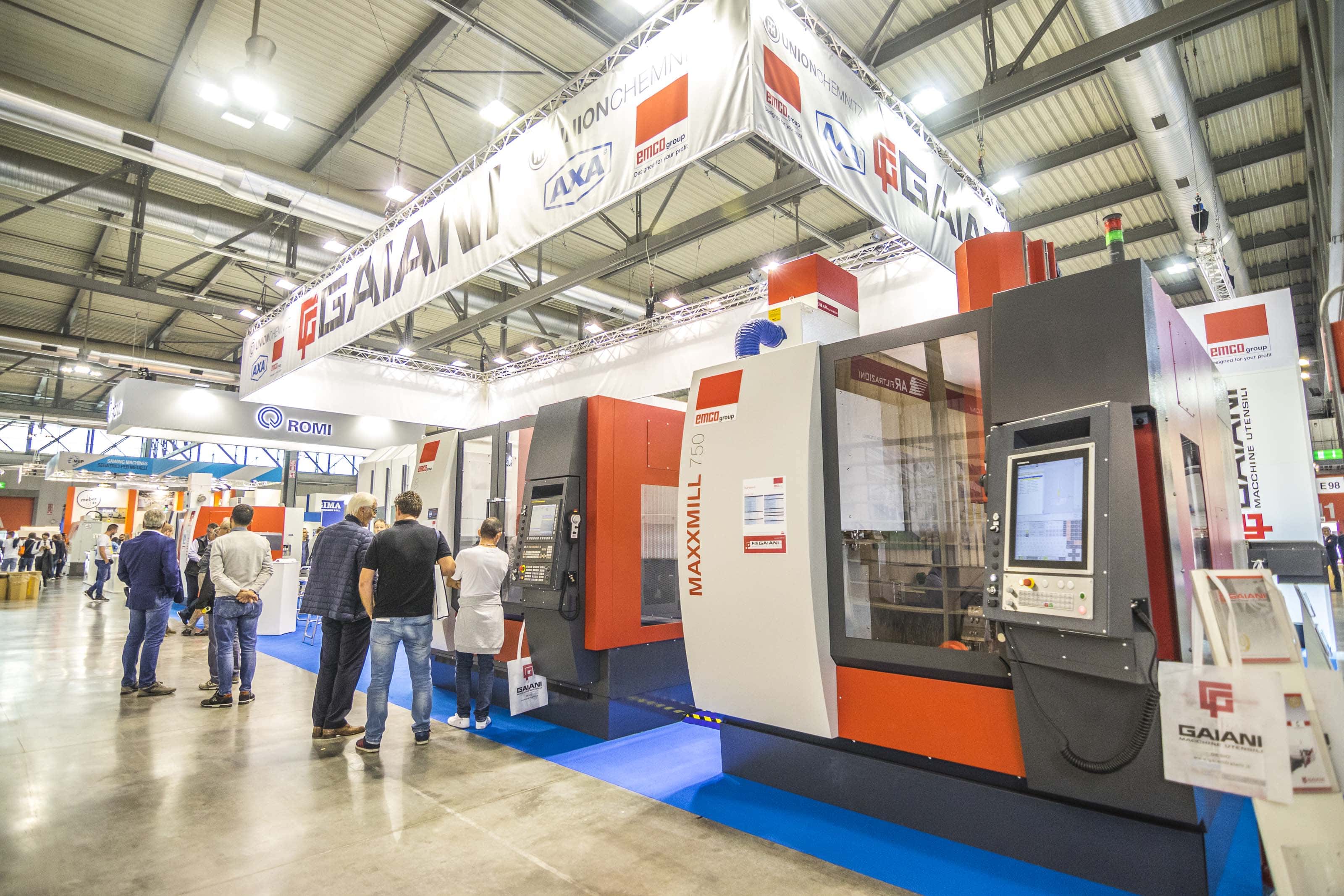

The multifunctional machining centers allow, with great flexibility, to perform a large number of mechanical operations such as: milling, boring, threading, drilling. Number of axes, size of working area, position of spindle and available options caracterize varìous types of machining centers on the basis of their configuration.

AR Filtrazioni has multiple solutions to solve the problem of oil mists and fumes deriving from the processing of almost all the brands of CNC machining centers.

Machining center

The multifunctional machining centres allow, with great flexibility, to perform a large number of mechanical operations such as: milling, boring, threading, drilling.etc. thanks to the possibility of a large number of tools in stock.

Number of axes, size of working area, position of spindle and available options caracterize varìous types of machining centers on the basis of their configuration.

Type of machining center

In any case, the most important upstream distinction is determined by the positioning of the spindle axis and consequently the classification in two macro categories: vertical machining centers and horizontal machining centers.

After the main classification of machining centers, we see how this information influences and determines the choice of the type of oil mist extractor and its optionals.

First of all, it is important to define the dimensions of the working area or operating field. The dimensions of the axes affect the maximum size of the worked pieces or possible production types and consequently the power of exhaust system to be equipped in terms of cubic meters / hour.

The list of all the technical characteristics of the machining centers is essential for AR FILTRAZIONI, to formulate an ad hoc offer.

In particular, some salient aspects are taken into consideration such as:

1 – type of coolant used or not;

2 – cutter power – spindle rotation speed;

3 – number of axes controlled;

4 – pallet changer system;

5 – utilize of high pressure pumps for lubrication;

6 – type of material worked;

7 – machine volume;

8 – distinction between horizontal and vertical machining center.

All these informations are important and have be taken seriously into consideration whenever you are going to buy a mist collector for your machine tool.

Depending on the type of production required, it is presumed that particular types of pollutant will be generated during the metalworking machining processes and consequently a suitable air purifier has to be suggested.

READ MORE ON CNC MACHINING CENTERThe types of pollutants produced during metalworking machining processes

For example, the oil mists produced during metal working with emulsified oil, are caused by the sum of these factors:

- – evaporation of the coolant oils and consequent production of fumes, oil mists and aerosols.

- – atomization of the oil caused by the high number of spindle/cutter revolutions and by the use of high pressure pumps of coolant oil on machine tool.

The resultant of these two elements physically breaks down the fluids into particles, micro-dusts and micro-mists so thin as to make them volatile.

Particular processings or types of material impose a dry metalworking, without liquid coolant.

When dry powders reach minimum dimensions become volatile and during processing/cleaning they remain suspended in the air.

We need underlining that in dry mechanical processes, powders and dusts are not the only pollutant; industrial fumes and aerosols also derive from the evaporation/combustion of protective grease/spray residues and coolant oils, remained on the surface of the workpiece throughout production chain.

The problem of oil mists-dusts-fumes if not held in mechanical workshops.

The volatility of polluting particles such as industrial fumes, oil mists and aerosols, whether solid or liquid, entails and creates various problems for metalworking companies, operators and machine tools.

First of all, they negatively affect the health of the air and the health and hygiene conditions of the operators, in particular at the respiratory level, since the particles smaller than 0.3 microns can reach the pulmonary alveoli, compromising the respiratory tract.

Not only that, in contact with the epidermis, they create skin irritations, dermatitis and redness.

From the production point of view, micro-dust and oil mists pollution in the workshop considerably reduces the productivity and in particular the efficiency of the machine tools, since the stratification of pollutants invalidates the precision and tolerance of the measuring instruments, with the onerous consequence of having to increase maintenance on the most delicate components.

Dusts, oil mists and aerosols not filtered and purified, make the floor slippery, dirty the surfaces of the machine tools and the walls of the shed, on which they settle.

Without forgetting any possible fines deriving from current regulations, which impose a concentration limit for oil mists in the workplace.

Italian TLV limit 5 mg / m3

more restrictive ACGIH limit 0.5 mg / m3

AR FILTRAZIONI APPLICATIONS | CNC machining centers

Discover our ideal series of industrial air cleaners ideal for all types of processing and pollutants

Choose the brand of your machining center

THE AIR CLEANER FOR YOUR NEEDS

CHOOSE YOUR RIGHT SOLUTION

Select by

MACHINERY

Choose the processing type and consequently the desired machine. You can choose the ideal filtration unit for your machine.

Learn how to reduce oil consumption, save on conditioning and reduce CO2 emissions.

Fill out the form and our calculation system will immediately quantify the savings you can get and send you the results by email.